Bicolor level gauges are a variant of glass indicators and are used to measure the level of steam and water inside a boiler. These instruments consist of a carbon steel body with a trapezoid cross-section, machined to create a longitudinal chamber and frontal holes evenly distributed on the two non-parallel faces. An illuminator colours the fluid (water) and steam with two distinct colours.

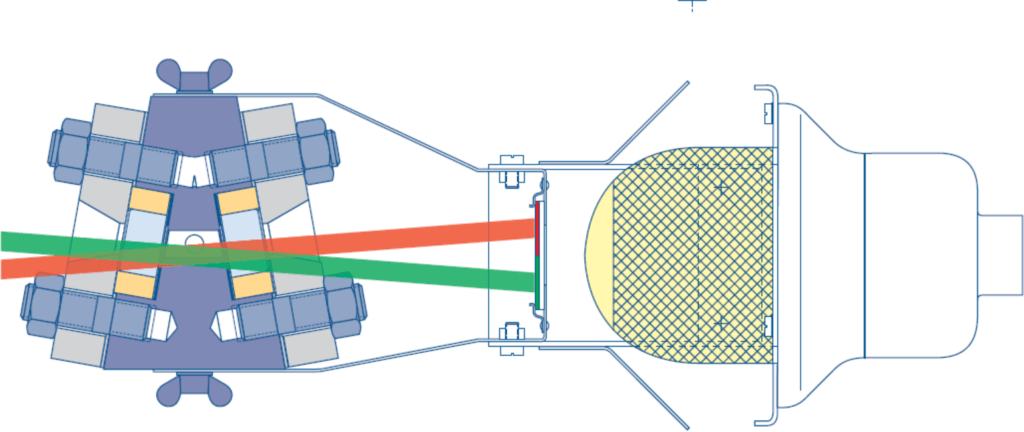

Bicolor level gauges are in principle transparent gauges in which the center piece has a wedge-shaped section. This design makes bicolor indication possible: there is an illuminator on the back with two colored filters positioned in front of the light source, one red and one green.

When viewed from the front, the red filter should always be placed on the left, in the narrowest part of the indicator section.

The optical separation between the space occupied by steam and that occupied by water is based on the different refraction of light in the two fluids.

The bicolor indication is produced by the red and green light rays:

This phenomenon occurs due to the different speed at which the red and green light rays travel. As they pass from one optically different medium to another, the speed at which the light waves propagate varies, causing the two colors to refract at different angles.

Bicolour level gauges find application in industries where the measurement of steam at medium and high pressures is necessary. They are mainly employed when accurate monitoring of water and steam levels is critical to ensure process safety and efficiency.

These indicators provide a clear visual indication of the level, with green representing the liquid (water) zone and red representing the vapor zone. This colour distinction greatly simplifies monitoring for operators.