Spiralwound gaskets are sealing devices designed to meet extreme temperature and pressure challenges. Despite this, these gaskets offer remarkable elasticity under any operating condition.

The name Spiralwound is derived from the manufacturing method: turns of preformed V-shaped metal tape are wound with an inorganic filler into spiraling coils until the desired diameters are achieved. The shape and this special construction method allow Spiralwound Gaskets to be able to tightly adapt to flange movements during heat cycles, thanks to the really high elasticity.

Based on the operating conditions in which the gasket will be operating, there is the option to choose the best suited materials to achieve better sealing. Different combinations of metal tape and filler ensure different performance.

In this article we discussed of Spiralwounds characteristics and production methods in more detail.

Usually, the thicknesses of the Spiralwounds we work with most frequently range from 3mm, up to 7.2mm, with a strong trend toward our customers' use of Spiralwounds with a thickness of 4.5mm.

Recently, we received a request for the production of Spiralwounds with a thickness of 10 mm, which proved to be a challenge for our production manager Said Ibrahim:

"In the initial phase of the feasibility study, we had to consider all the variables to be controlled for the production of gaskets of this thickness."

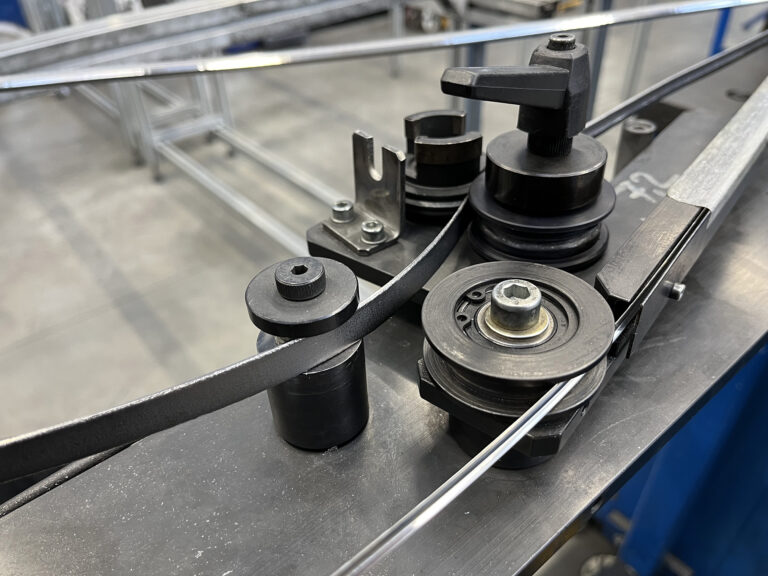

The biggest challenges were found precisely in adapting the machine to manifacture a thickness we were not used to working with.

In addition to the high thickness, these Spiralwounds were 3.5 meters in diameter. The combination of these two parameters presented us with an even greater challenge.

Another issue we faced involved transportation. As with all large gaskets, any handling poses a difficulty and in this case such arrangements were made to best protect any handling of the gasket: in addition to an outer protective packing made of silicone mousse that wrapped the entire gasket, rigid elements were added both internally and externally to prevent any movement of the gasket.

Whether it is the production challenges arising from special dimensions or handling the transportation of these gaskets, at KLINGER Italy we are ready to meet every challenge, setting as our ultimate goal our customers’ satisfaction.