Spiralwound gaskets provide a reliable and innovative solution when operating conditions exceed the temperature and pressure limits of traditional plastic gaskets, such as asbestos-free or graphite-based gaskets.

A Spiralwound gasket is a sealing device designed to meet the challenges of extreme temperatures and pressures while offering remarkable elasticity under all operating conditions. These gaskets are ideal for applications where traditional seals are no longer sufficient. The construction of a Spiralwound gasket involves alternating turns of V-shaped preformed metal tape and inorganic filler. This unique combination of materials results in exceptional sealing performance.

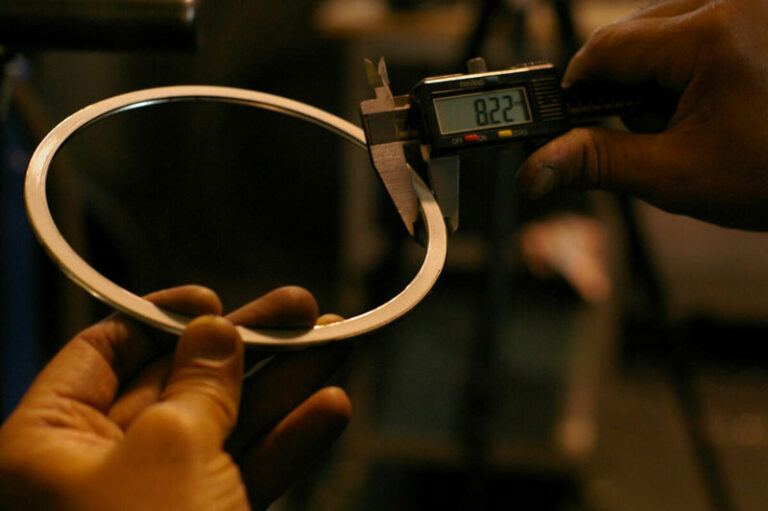

Spiralwound seals can be manufactured in a variety of materials, providing the flexibility to suit the specific needs of the application. KLINGER Italy’s modern machinery enables it to produce Spiralwound gaskets in sizes ranging from 12 millimeters in diameter to over 4 meters. In addition, the ability to vary the winding density (No. Turn/mm) is a key element in achieving the best sealing results and meeting the required fugitive emission levels.

Spiralwound seals offer numerous advantages that make them an outstanding choice for applications where operating conditions are extreme. Some of these are:

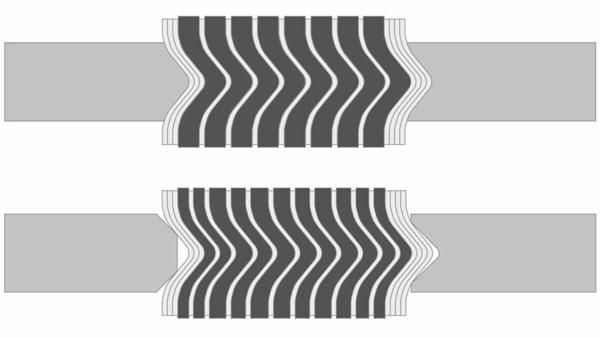

Variable Stiffness: One of the distinguishing features of Spiralwound gaskets is the ability to adjust their stiffness by playing with the number of turns. This allows the gasket to be precisely matched to the specific needs of the application. In situations where the compression of the gasket must be precisely calibrated, this flexibility is critical to ensure a reliable seal.

Superior Elasticity: The unique V-shape of Spiralwound gaskets is a key element that makes them highly elastic. This characteristic allows them to adapt to flange movements, even when subjected to heat cycles. The gasket follows deformation, ensuring seal stability and operational safety.

Spiralwound gaskets are a versatile and reliable choice for applications where conventional plastic gaskets fail. With their adjustable stiffness, superior elasticity and focus on sealing, these gaskets ensure the safety and reliability of industrial operations. In addition, their compliance with environmental regulations makes them a sustainable choice for the future. Choosing Spiralwound seals means relying on a solution that is perfectly suited to the specific needs of the application.