The experience of our customers leads them to request very specific Level Gauges; they know their plant to perfection and already know which Gauges are best suited for their applications.

KLINGER Italy is able to meet the most demanding requests, and at the same time offer design support in choosing the most suitable Level Gauge, with respect to which type is most fitting in a given environment. Especially in choosing whether to apply a Glass or Magnetic Level Gauge.

In Glass Level Gauges, the fluid level is controlled with the help of crystals. Among these we can find two types: Transparent Level Gauges and Reflective Level Gauge.

In Transparent Level Gauges, the fluid passes through two smooth-surface crystals, making it very easy to read, giving the possibility to check not only the level but also the color of the fluid.

In Reflex Level Gauges, the phenomenon of refraction is used due to a crystal with a flat and a prismatic surface in contact with the fluid: light will be totally absorbed by the fluid, appearing dark in color, while the absence of fluid will totally reflect it, appearing light in color.

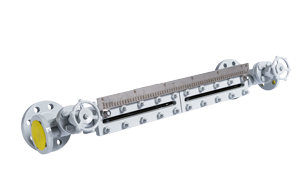

These Level Gauges make use of a float with a magnet inside of it. As the Fluid Level rises, the float will move high-contrast flags along with it, making the Fluid Level easy to read.

The main difference between these two macro categories can be found in the safety that Magnetic Indicators provide. Through the use of special lamellae made of MICA or Ethylene Tetrafluoroethylene (ETFE), Transparent Level Gauges can also be used in systems with more aggressive fluids, but the glass always represent danger points when compared to the hermetic tube that makes up Magnetic Level Gauges. The latter, are in fact recommended when toxic or even deadly fluids need to be checked.

We can also achieve an additional level of safety by equipping the Magnetic Level Gauges with a transmitter. This allows the level to be detected remotely, from a control room, without having to be physically present on the plant. It also gives you the ability to activate electrical circuits remotely.

If maintenance costs are to be considered, Magnetic Level Gauges are still the best choice, as their maintenance is close to zero. In Glass Level Gauges, the wear and tear of the seals that go into insulating the crystals, but also the crystals themselves, must be taken into account. Although the cost is very low, in installations with multiple Level Gauges, the cost can add up.

Magnetic Level Gauges, can also be made with longer connections, as Glass Level Gauges, beyond 3/4 meters in lenght, encounter the phenomenon of bending which can damage the crystals.

Although they are used in similar applications, the differences in these Level Gauges are substantial and can affect not only the safety of a plant, but also its maintenance costs.